In the Inventor Sheetmetal environment, users take advantage of the unfold functionality for creating flat patterns of a wide variety of materials. Although not necessarily the norm, I do get asked from time to time about removing the bend relief (cut away) from a flange.

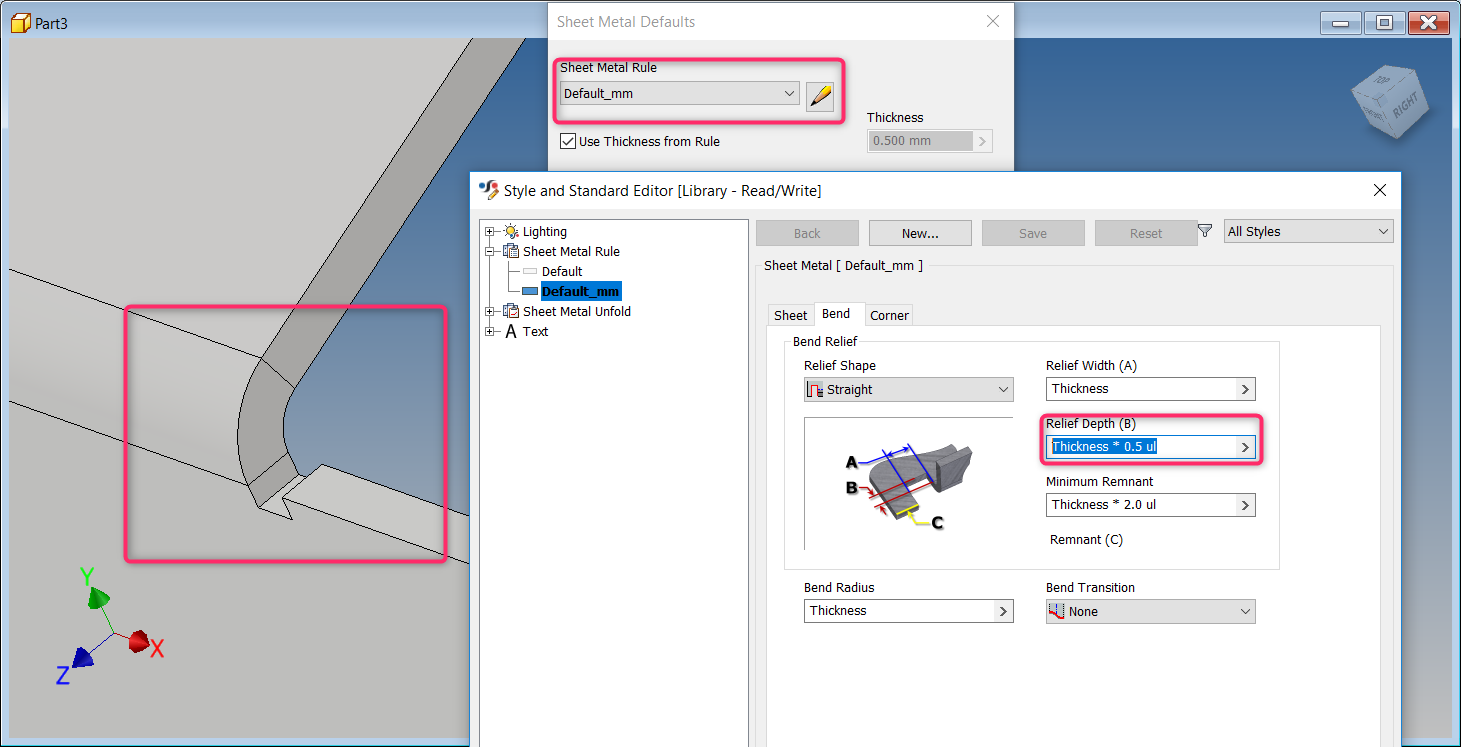

There are a few ways to do this and I always suggest modifying the particular flange edge ‘Relief Depth’ to a value of zero (0). This will work in the majority of cases or you can set your Sheetmetal rule to do this in all cases as you design.

The other way to do this would be to create a sketched feature and extrude to consume the solid faces in the model. In the Inventor Sheetmetal environment you can model as usual as long as your material remains constant and the unfold won’t self intersect.

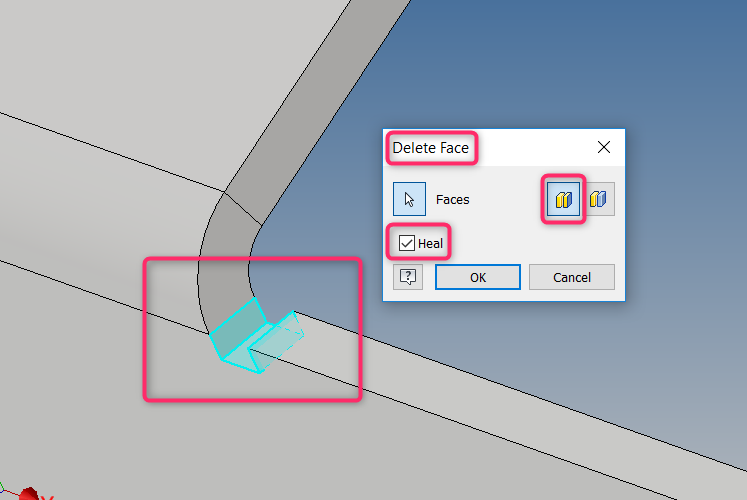

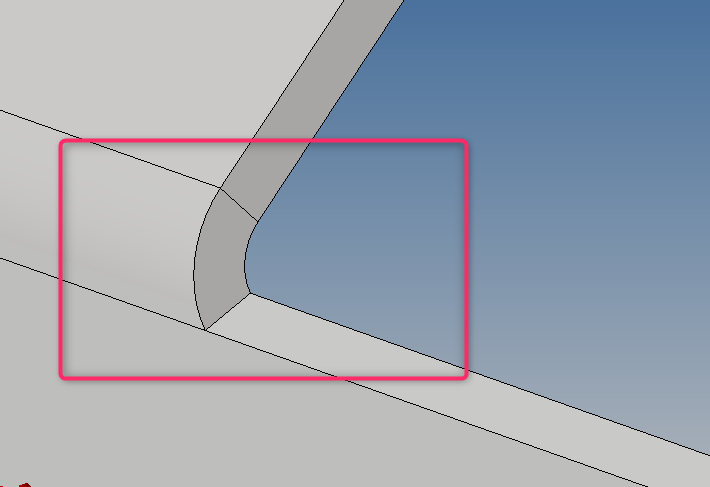

With the above being the case, I would also suggest using the Inventor ‘Delete Face’ command. This is a very useful tool and apart from removing and healing a multitude of sins which may have occurred in a model (perhaps it has been translated from another system), it too can be used to take out unwanted model bits, cut-outs, faces and even holes.

The key when using these modelling methods is to make sure, and take care, that you are not changing the material and thickness, otherwise the design won’t unfold.